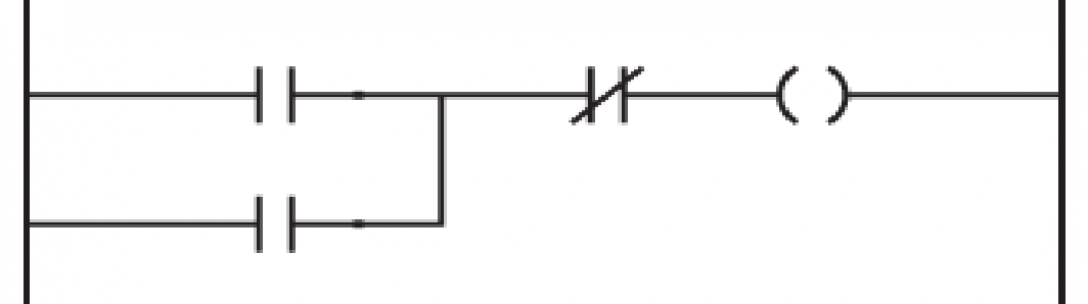

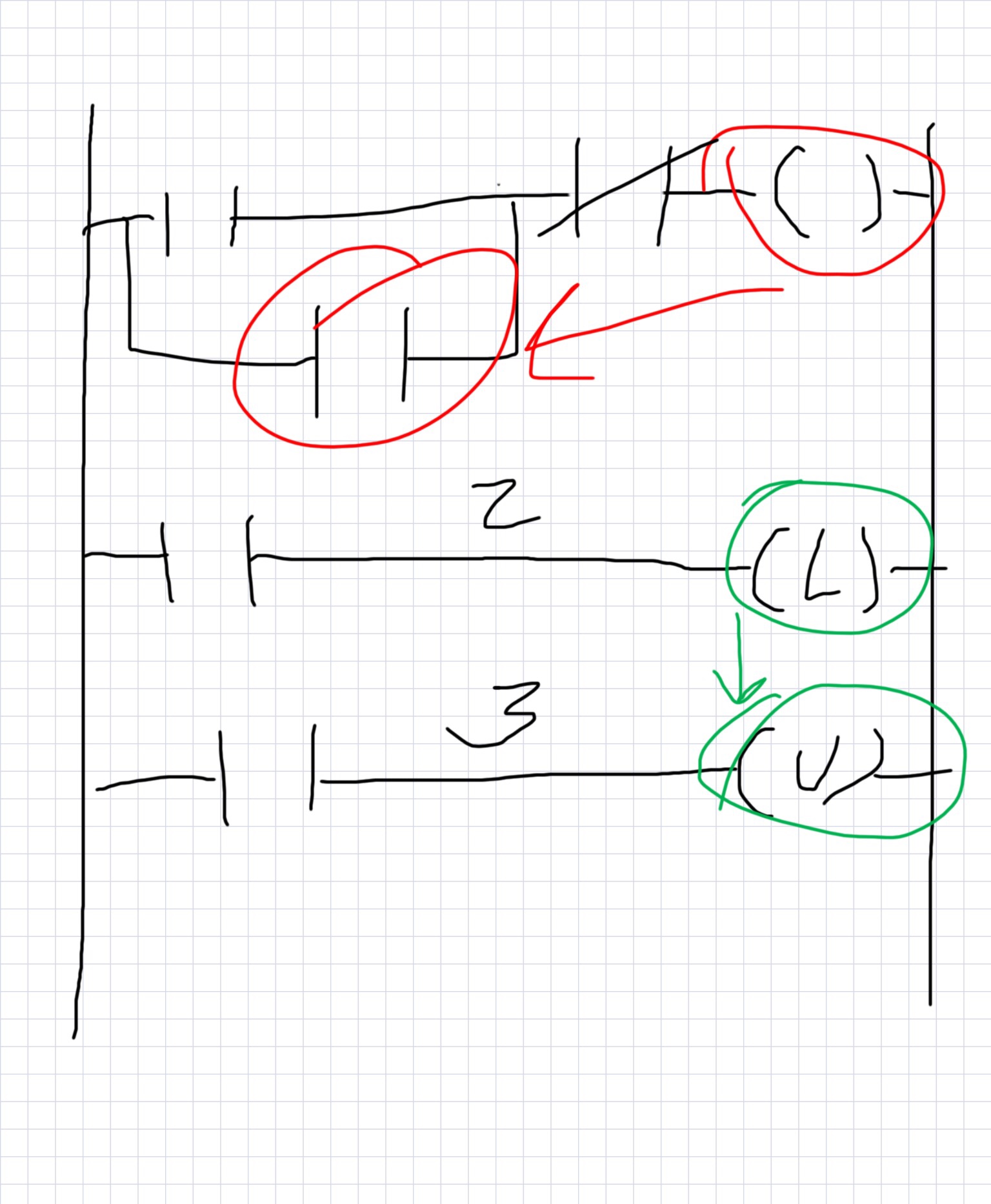

The problem: You have a process that reacts badly when it is energized too quickly (almost every process I touch). This is not a big issue if you have some way to slowly ramp your energy/feed source from a valve, VFD, temp regulator etc…that and a PLC attached to your process with analog output ability. First thing to detmermine on the programming end is how your PLC outputs its signal to your process. For example: is your output 4-20 mA, 0-10V…etc. and how exactly is that translated in your program. When you send a command to the output does it need to be a number from 0-32767, 0-100 percent, or a number related to your process. Second, determine how long you want to ramp and convert it to your PLCs default timer time. ControlLogix does time in milliseconds. So if you want a 10 second ramp you would have to convert it to 10000ms. Now what needs to be done is find out how your time relates to your output. We will go for an easy example of 0-32676 bits out to 10 seconds. So 0 = no output and 32676 = 100 percent output (if you want to ramp to 100%). We will opt for going from 0 to 100% in 10 seconds. If we want this divide 32676 by 10000ms and we get 3.2676 bits per ms. Now, determine what you want to start your ramp (start button, limit switch, proximity switch output, etc…). Latch the bit, as seen in the last blog post. (Simple Latching in a PLC) Now fire a timer (TON) with your latch bit. We want to set the timer to the amout of time you want to ramp, 10000ms is our example. We use the accumulation integer to determine where the timer is in the process and to ramp up the process (yourtimer.ACC in Logix). Now on a branch under the timer convert to your PLCs output using a MUL(multiply) so you will be multiplying your .ACC integer to your factor of 3.2676. This number is what you want to put into your output card with a MOV(Move) instruction. Do this with a bit that comes on while you desire ramping. This can also be a ramp bit or alternatively it can be the timer timing bit (.TT). This will send your output only while your timer timing is high. There are many ways to set and reset your timer/s from here. You may also want to use a recantation timer (RTO) and just user the .ACC to selectively ramp at certain times. If you do this you would also need to reset the timer with a (res) bit. I will post some screenshots or drawings for this soon but for now…I hope this helps you when programming ramps.

Luke

==